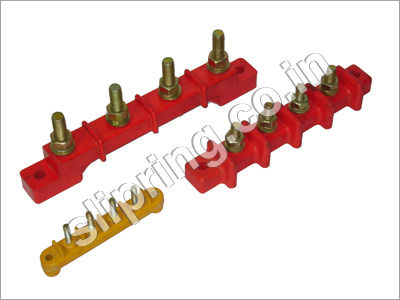

Generator Terminal Plates

Generator Terminal Plates Specification

- Insulation

- Industrial grade bakelite/ceramic

- Dimension (L*W*H)

- Varies as per generator model

- Protection Class

- IP 23 or as requested

- Rated Frequency

- 50/60 Hz

- Phase

- Single Phase/Three Phase (as required)

- Color

- Black/White/Brown (as per material)

- Weight

- Varies by size

- Flame Retardant

- Yes

- Surface Finish

- Smooth/Glazed

- Heat Resistance

- Up to 150°C

- Terminal Type

- Copper/brass studs

- Application

- Suitable for all types of generator sets

- Number of Terminals

- 3, 4, 6, or as per customer requirement

- Current Capacity

- Rated up to 100A or more depending on type

- Material

- High quality electrical grade bakelite or ceramic

- Customization

- Available as per specifications or drawings

Generator Terminal Plates Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- Piece

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Middle East, Africa, Western Europe, Eastern Europe, South America, Central America, Australia, Asia, North America

- Main Domestic Market

- All India

About Generator Terminal Plates

We are a well-renowned organization, engaged in manufacturing, exporting and supplying an excellent quality range of Generator Terminal Plates. Under the guidance of our adroit experts, these terminal plates are manufactured using quality approved raw material with the help cutting-edge technology. Offered plates are used in different machines and electrical appliances for electrical and current conductivity. Additionally, these Generator Terminal Plates are offered in various specifications as per the requirements of clients.

Features:

-

High class insulation

-

Rust proof

-

Robust design

-

Heat resistance

Superior Material Quality and Safety

Each generator terminal plate is crafted from industrial-grade bakelite or ceramic known for its exceptional insulation and durability. Flame retardant and heat resistant up to 150C, these plates offer assurance of safety and longevity, making them ideal for continuous operation in varied environments.

Versatile Terminal Configurations

Available with 3, 4, or 6 copper/brass studs, and customizable as per your project requirements or specific drawings, these terminal plates can easily adapt to a wide spectrum of generator models and capacities. Their flexibility ensures compatibility with both single-phase and three-phase generator sets.

Custom Solutions for Every Application

We offer generator terminal plates with tailored dimensions, protection class (IP23 or as required), and color options. Whether you need plates for new installations or retrofit purposes, our manufacturing process ensures each unit meets customer specifications, optimizing both performance and reliability.

FAQs of Generator Terminal Plates:

Q: What materials are used in the manufacturing of generator terminal plates?

A: Our generator terminal plates are constructed using high-quality electrical grade bakelite or ceramic, with copper or brass terminal studs to ensure excellent conductivity and insulation.Q: How can these terminal plates be customized to fit specific generator models?

A: We provide customization based on your specifications or technical drawings, including the number of terminals, dimensions, protection class, and color, to ensure compatibility with any generator model.Q: When should I replace my generator terminal plate?

A: It is recommended to replace the terminal plate if there are signs of physical degradation, reduced insulation, or overheating, which can impact safety and efficiency.Q: Where can these terminal plates be used?

A: Our terminal plates are suitable for all types of generator sets used in residential, commercial, and industrial sectors, offering reliable performance across diverse environments.Q: What is the installation process for these terminal plates?

A: Installation involves securely mounting the plate in the generator set, connecting the electrical wires to the appropriate copper/brass studs, and ensuring all terminals are firmly fastened for optimal conduction and safety.Q: How does the design benefit generator operation?

A: The smooth/glazed finish, durable materials, and high heat resistance ensure superior insulation, minimal maintenance, and safe power distributionultimately enhancing the overall reliability and life of the generator set.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in TERMINAL PLATE Category

DMC Terminal Plates

Price 2000 INR

Minimum Order Quantity : As per requirements Piece

Weight : Lightweight (Varies on model size)

Color : Gray/Red (Other colors possible on request)

TERMINAL PLATE for STAMFORD ALTERNATOR

Price 1750 INR

Minimum Order Quantity : 1 Piece

Weight : Approx. 150300 g

Color : Silver/Metallic

Product Type : Terminal Plate

ABB TERMINAL PLATE

Minimum Order Quantity : As per requirement Piece

Weight : Approx. 50100 grams

Color : Off White

Product Type : Terminal Plate

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS