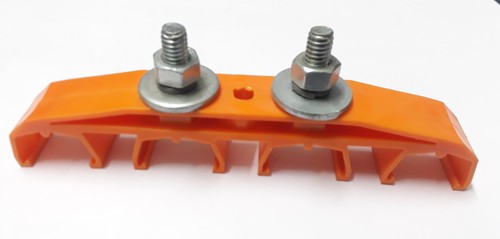

CURRENT COLLECTOR 250AMP

CURRENT COLLECTOR 250AMP Specification

- Efficiency

- >98%

- Humidity %

- 90% RH (Non-condensing)

- Connector Type

- Spring Loaded Carbon Brush

- Shape

- Rectangular

- Power Factor

- 0.95

- Surface Finish

- Powder Coated

- Overheating Protection

- YES

- Mounting Type

- Bolted

- IP Rating

- IP23

- Feature

- High Conductivity, Corrosion Resistant

- Operating Temperature

- -10C to +70C

- Insulation Material

- Fiberglass Reinforced Plastic

- Product Type

- Current Collector

- Application

- EOT Crane & Conductor Bar System

- Protection Level

- IP23

- Frequency (MHz)

- 50 Hz

- Rated Voltage

- 415 V AC

- Energy Consumption

- Low

- Output Type

- AC

- Color

- Red & Black

- Dimension (L*W*H)

- 185 x 75 x 62 mm

- Weight

- 2.8 kg

- Size

- Standard

- Phase

- Three Phase

- Input Voltage

- 415 V

- Connection Type

- Screw Connection

- No Of Poles

- 3

- Material

- Copper Alloy & FRP

CURRENT COLLECTOR 250AMP Trade Information

- FOB Port

- NEW DELHI

- Payment Terms

- Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Middle East, Asia, Africa

- Main Domestic Market

- All India

About CURRENT COLLECTOR 250AMP

We are manufacturing current collector for DSL conductor shrouded bus bar. Current collector are available in different ampere capacity 60 AMP, 80AMP, 100AMP, 125AMP, 250AMP. We are also manufacturing Current Collector For Enclosed Jointless for angle type MS DSL bus bar in different Current capacity 250AMP, 500AMP, 800AMP, 1000AMP.

Product Details:

| Type | M Type Current Collector |

| Current | Up to 250 A |

| Voltage | 220-240 Volt |

Designed for Demanding Industrial Environments

Built with high-grade materials such as copper alloy and FRP, this current collector withstands the rigors of heavy-duty operations and harsh conditions often encountered by EOT cranes and conductor bar systems. Its powder-coated surface and robust insulation provide long-term protection against corrosion and overheating, ensuring reliable operation in high-humidity and varying temperature ranges.

Optimal Performance and Safety

The devices carbon graphite brush and precise contact pressure ensure stable current collection at maximum speeds of 100 m/min. It features built-in overheating protection and an efficiency rating exceeding 98%, making it both safe and energy-efficient. The IP23 protection level safeguards against dust and water ingress, while compliance with IS/IEC standards assures quality and reliability.

FAQs of CURRENT COLLECTOR 250AMP:

Q: How is the CURRENT COLLECTOR 250AMP installed on crane systems?

A: The collector is mounted using a bolted connection method, ensuring secure attachment to both EOT cranes and conductor bar systems. It utilizes a screw connection for electrical wiring, facilitating reliable and straightforward installation.Q: What are the main benefits of using a carbon graphite brush in this collector?

A: Carbon graphite brushes combine high conductivity with excellent wear resistance and self-lubricating properties, resulting in lower maintenance, consistent performance, and minimized energy losses during operation.Q: When should the current collector be replaced or its brushes serviced?

A: Routine inspection is recommended, especially when operating at high speeds or under heavy loads. Brushes should be checked for wear periodically and replaced at the first sign of excessive degradation to maintain efficient current flow and protect system components.Q: Where is the CURRENT COLLECTOR 250AMP most effectively used?

A: This device is specifically designed for heavy-duty cranes, mobile equipment, and industrial conductor bar systems, making it ideal for use in factories, warehouses, and applications requiring robust three-phase power transfer.Q: What processes ensure compliance with IS/IEC standards in this product?

A: Manufacturing adheres to strict IS/IEC guidelines, covering material selection, electrical performance, safety features, and rigorous quality control, ensuring each unit meets international standards for industrial current collection.Q: How does the IP23 rating benefit its operation?

A: The IP23 protection level secures the collector against the entry of solid objects over 12.5 mm and water spray at an angle up to 60 from vertical, enhancing its durability and reliability in demanding environments.Q: What energy efficiency features does the collector offer?

A: With an efficiency greater than 98% and a power factor of 0.95, the collector minimizes power losses, helps reduce operational costs, and ensures sustainable energy consumption for large-scale industrial operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in EOT CRANE SPARES Category

EOT Crane Current Collector Holder 250Amps

Price 1000 INR

Minimum Order Quantity : 1 Piece

Color : Red & Black

Frequency (MHz) : 50 Hz

Feature : Corrosion resistance, Durable

Product Type : Current Collector Holder

4 POLE HANGER CLAMP

Price 250 INR

Minimum Order Quantity : 6 Pieces

Color : Black & Silver

Frequency (MHz) : 5060 Hz

Feature : High Tensile Strength, UV Resistant

Product Type : Pole Hanger Clamp

3 POLE HANGER CLAMP

Price 200 INR

Minimum Order Quantity : 12 Pieces

Color : Multicolor

Frequency (MHz) : 50/60 HZ

Feature : Electrical

Product Type : 3 POLE HANGER CLAMP

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS